-

Headquarters -

6260 Hwy 7 Unit 8, Vaughan, ON, L4H 4G3

-

Year established -

2007

-

NAICS -

333248 - All other industrial machinery manufacturing

-

Major expansions -

2016

-

Employees -

45

-

Exports -

U.S.

-

Download -

Proto3000

Based in Vaughan, Proto3000’s design, additive manufacturing, and metrology technologies help customers solve complex engineering and manufacturing challenges, resulting in shorter cycle times, more flexible supply chains, faster prototyping and more efficient production.

When a manufacturing company focuses on quality, perfection is the goal. Ensuring that the product has a positive impact on the customer is also paramount. If that customer is a child in need of life saving heart surgery, almost perfect isn’t enough – everything must be flawless. The partnership between Proto3000 and healthcare providers is based on the pursuit of perfection, enabling precision execution of critical cardiac surgery for the patients in their care.

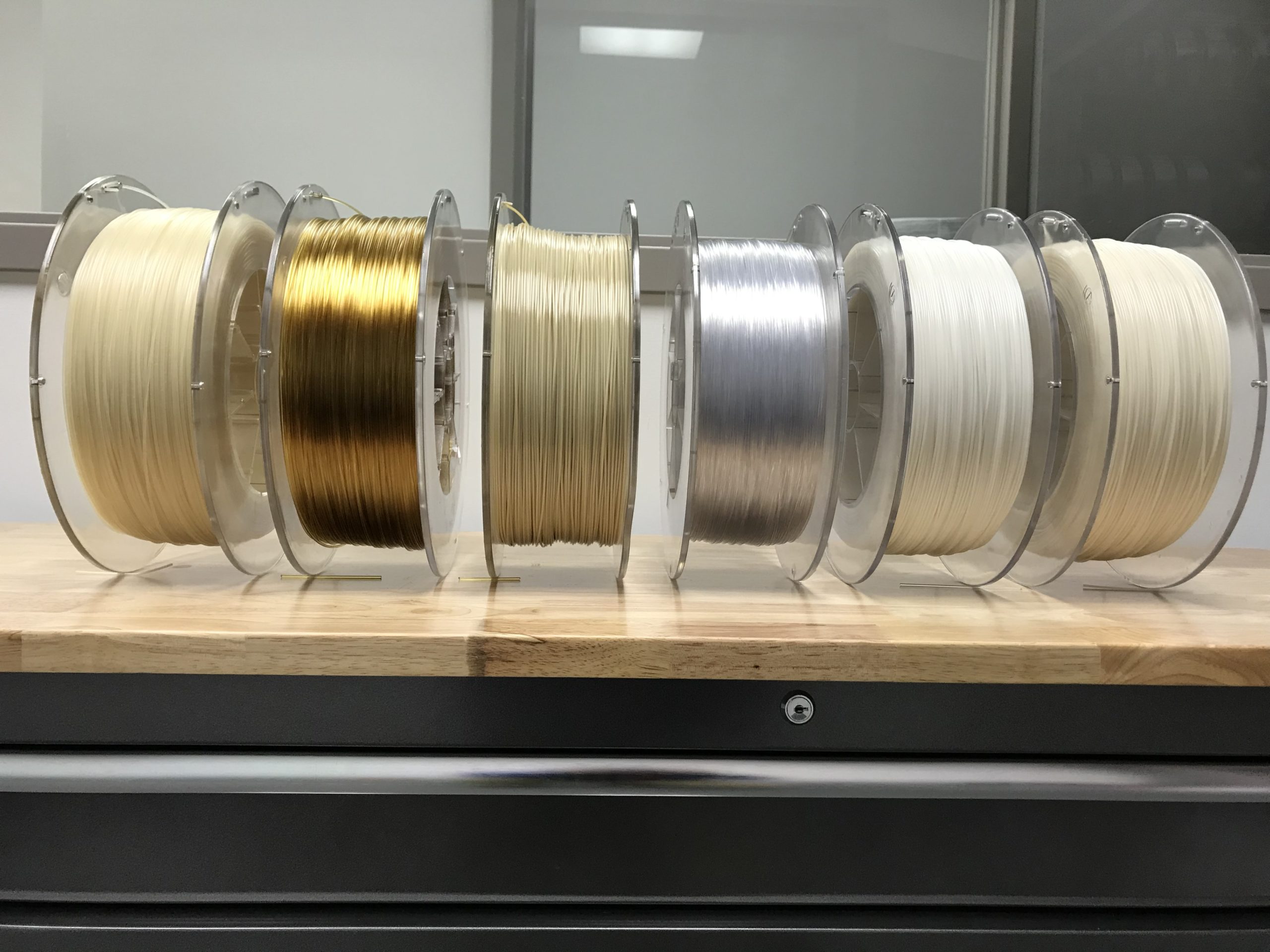

Based in Vaughan, Proto3000’s design, additive manufacturing, and metrology technologies help customers solve complex engineering and manufacturing challenges, resulting in shorter cycle times, more flexible supply chains, faster prototyping and more efficient production. The company’s solutions are two-pronged, offering the option of implementing product solutions into a business, or leveraging service offerings as part of a supply-chain. The services the company offers include professional 3D printing, 3D CAD modeling and design, engineering, rapid prototyping, low-mid volume production, 3D scanning, and quality inspection. The company also distributes lines of design software, 3D printers (both metal and polymer) and scanners.

Proto3000 recently obtained a Medical Device Establishment Licence (MDEL), which allows them to manufacture medical devices in Canada.

Proto3000 was founded in 2007 by Eyal Geiger, President and John Frangella, Chief Executive Officer. When Greiger and Frangella met, their shared appreciation for the potential transformative impact of additive manufacturing technologies led them to start their business with one machine in a basement. A year later, it moved to a 3,500 square foot location in Vaughan on Marycroft. In 2016, with the industry rapidly growing, and having outgrown that space, the company moved to its current 16,000 square foot manufacturing facility. Today, Proto3000 employs 45 people across three locations. In addition to the plant and headquarters in Vaughan, the company has offices in Laval, Québec, and Atlanta, Georgia, to serve customers in the aerospace, automotive, manufacturing, education, consumer products, medical, and dental industries.

Proto3000 was one of the first companies in North America to receive ISO certification for the delivery of 3D printing, scanning, and CAD engineering services. It competes with US-based companies significantly larger in size and scale. The company describes a customer-centric approach to collaborative problem solving as its value proposition. It uses smaller opportunities to break into new customers, leveraging those initial projects to introduce additional applications and expand its footprint. Those applications include product development, tooling, manufacturing, molding and production parts.

In Ontario, the company helps OEMs and parts manufacturers use Proto3000 tools to produce parts on demand using digital inventory and create more agile supply chains.

The company is especially proud of its accomplishments in the medical and dental fields. Proto3000 recently obtained a Medical Device Establishment Licence (MDEL), which allows them to manufacture medical devices in Canada. The company’s current work with leading medical institutions and academic research facilities across the country involves producing anatomical models used in surgical planning and training. For example, the company’s models of hearts, produced through additive manufacturing processes, allow clinicians to practice intricate cardiac surgeries in a life-like setting. Proto3000 also provides the technology and expertise to dental labs and clinics to manufacture dental devices and orthodontic models, including the popular clear aligners that have replaced traditional orthodontic braces for many patients. In the wake of the COVID-19 pandemic, Proto3000 pivoted quickly to produce much-needed PPE, specifically face shields, producing hundreds of thousands of units to date.

Proto3000 has made substantial contributions to advances in automotive technologies and manufacturing processes. Customers like Magna look to the company to produce tools that aid in the assembly process, prototypes, and parts as well as guidance on how to implement additive manufacturing into their business model. In Ontario, the company helps OEMs and parts manufacturers use Proto3000 tools to produce parts on demand using digital inventory and create more agile supply chains. Magna (Canada’s largest manufacturing employer) is a key customer with which Proto3000 enjoys a collaborative problem-solving relationship that helps Magna satisfy the demands of supplying automotive OEMs.

Additive manufacturing is relatively new for many Canadian manufacturers. While it offers competitive advantages, including increased speed to market and faster prototyping, many manufacturers have yet to embed additive manufacturing into their operating models. To support the more widespread adoption of additive manufacturing in Canada, Proto3000 works directly with their clients to create a roadmap for integration. Along with expert advice, they produce educational material, and share success stories of the technology being used from across the world through its online channels, to raise awareness about the advantages of these processes.

The dearth of persons familiar with additive manufacturing presents a challenge for Proto3000. To overcome these challenges the company provides employees with on-the-job training, and encourages post-secondary institutions to expand their additive manufacturing-related curriculum. As Sheridan alumni, the co-founders employ many of their fellow Mechanical Engineering graduates from the college. Partnering with McMaster, York and Sheridan, Geiger and Frangella offer insights to embed additive manufacturing into their curriculum. The company has also set up 3D printers at elementary and secondary schools to encourage earlier exposure to additive manufacturing technologies. This early-stage outreach is intended to reach future employees and customers.

Proto3000 sees a role for government and industry associations in supporting its efforts. Currently, the company faces challenges from large American competitors that have better access to capital and raw materials used in additive manufacturing. These companies received significant investment during the Obama administration, which allowed competitors to scale up quickly. American companies also benefit from a competitive tax environment, a larger labour pool, and support networks that build awareness of how additive manufacturing can positively impact productivity in multiple sectors. Proto3000 looks to governments in this country to promote more of a “buy Canadian” approach to sourcing.

Proto3000 is contributing to the adoption of Industry 4.0 in Canada. The company’s founders believe that additive manufacturing can play a vital role in the advancement of sectors including aerospace, automotive and consumer products. Helping companies make better products that will improve their customers’ experiences is an important goal. Given that the company is already helping surgeons perfect the technique required to save a patient’s life suggests that Proto3000 is well on its way toward making its mark.

For more information about Proto3000, visit Website.

Published: April 20, 2021

Angstrom Engineering

Angstrom Engineering Inc. is a leading manufacturer of thin film vacuum deposition equipment and vacuum chambers equipment. The firm specializes in designing, manufacturing, selling and servicing machines that deposit thin films, (growing layers of materials on a substrate with thicknesses that can range from less than one nanometer to several microns).

Transformix Engineering

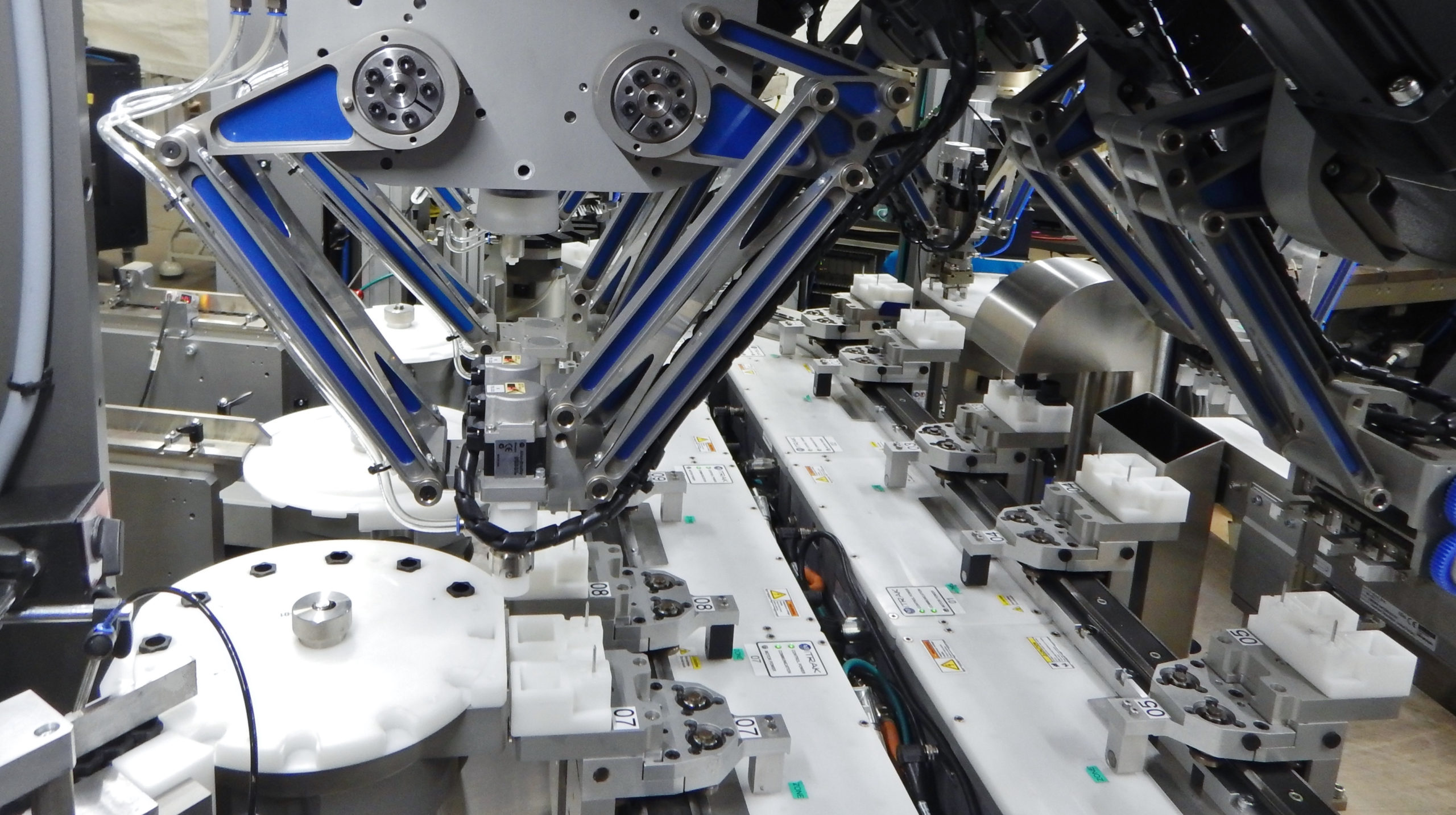

Transformix Engineering is exclusively focused on CNCAssembly® technology in the specialized niche of "continuous motion", and have developed it into a general solution for small-part assembly.

BOS Innovations

BOS Innovations develops custom factory automation solutions to help companies reach greater levels of productivity and profitability. The company’s mission is to advance North American manufacturing through world class integration of automation systems with innovative engineering, build quality, and service.

Next Manufacturing

Headquartered in Whitby, Ontario, Next Manufacturing Inc. specializes in fused deposition modeling, a process that enables 3D printers to manufacture products by depositing melted material in a predetermined path one layer at a time.

Axiom Group Inc.

Axiom Group Inc. has a long history of forward-thinking and technological innovation. When Industry 4.0 presented opportunities to further improve operations, they were ready.